Manage on-site PLC data from the office PC via direct serial connection or Ethernet

Tellus & V-Server

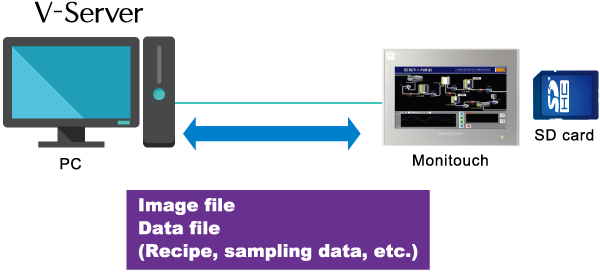

Motion Control | HMIIn Tellus HMI mode, manage on-site PLC data from the office PC via direct serial connection or Ethernet with PC peripheral equipment and Windows application software. V Server accesses PLC from the office PC via MONITOUCH through Ethernet to collect real-time data without additional programming. Together, this cost-saving software package enables you to monitor and operate your plant, anywhere, anytime. Onsite Monitouch data can be accessed and used for remote maintenance from your office PC. V-Server enables easy data collection and management of real-time onsite data. Quick recovery of production lines is possible with no extra cost and no loss of time. Real-time monitoring from remote locations and solving problems without visiting the site helps maintain uptime and production.

Features & Benefits

Features

01 Data saving without programming

Data logging function

Production data can be regularly read out and saved in database, CSV / Excel format.

Readout of sampling data

Sampling data stored in Monitouch can be read out and saved in database or CSV / Excel format.

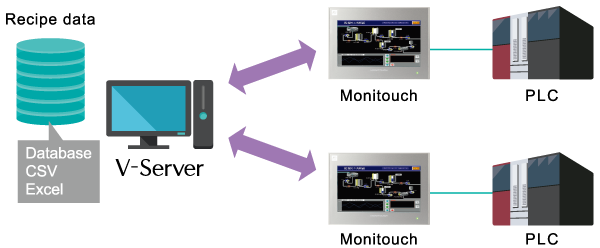

02 Consolidated recipe data management

Consolidation of recipe data by the upper-level PC reduces the process of recipe registration and modification for each piece of equipment and provides consistent product quality.

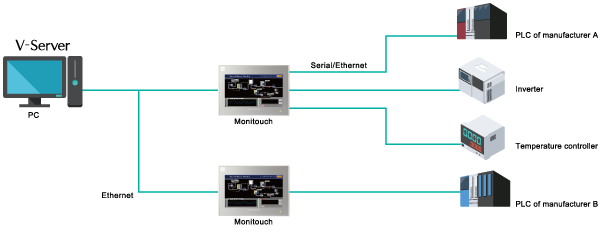

03 Consolidated management of data of PLCs of various types and manufacturers

V-Server collects information from peripheral devices through Monitouch as a gateway.It is possible to collect information from the devices of any type and manufacturer if they can be connected to Monitouch.

04 Easy to make daily and monthly reports (DDE function)

The tag data registered in V-Server can be pasted to Excel files in DDE format.This makes it easy to generate daily / monthly reports.

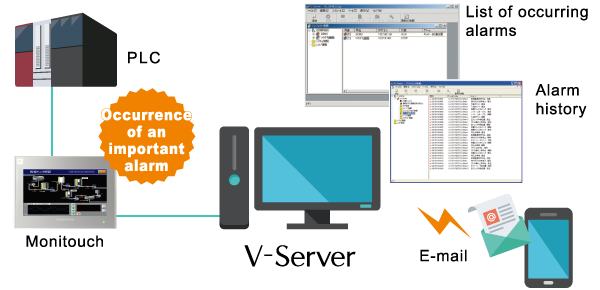

05 Quick response to on-site problems

Alarm data can be monitored to display historical data or a list of alarms currently occurring. In addition, an e-mail alert can be sent immediately when a critical alarm occurs.

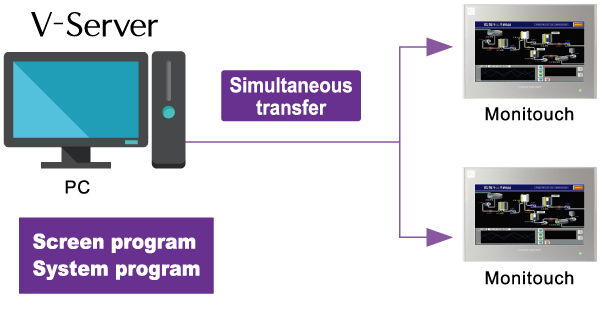

06 Updating of Monitouch data from the office

You can update the system program of multiple Monitouch panels at a time or transfer the screen program to them all together.

07 Reading and writing of stored data

Files on a SD card inserted in Monitouch can be read out to a PC, and fikes edited on a PC can be written onto a SD card via Ethernet.

08 Automatic actions in response to events

Various kinds of events can be set depending on the requirements of the operation. Events allow for a high degree of fkexibility, so you can adapt to the specifications of the production line.

.png?width=600&name=image_09-1%20(1).png)

Documentation

Brochures and Catalogs

Specifications

Solutions

Energy and Utilities

In energy and utility segments, increasing efficiency and cutting down waste are some of the key challenges many ...

Water and Waste Water

Most of the energy consumption in Water and Waste Water Treatment Plant (WTP) is electric power consumption it is ...

Services

Fuji Electric offers a wide range of design and consultation services related to the development of solutions in all of the industry sectors we operate in. Each project requires specific inputs and deep expertise to create the best possible solutions

China

China Europe

Europe France

France Hong Kong

Hong Kong Indonesia

Indonesia Japan

Japan Singapore

Singapore Thailand

Thailand USA

USA