Easy and accurate flow measurement without interrupting processes

ULTRASONIC FLOWMETERS

Process AutomationFuji Ultrasonic Flowmeters offer easy and accurate flow measurement without interrupting processes. They can be easily clamped-on to existing pipes

They are suited for a wide range of liquids, for example, deionized water, cooling water, chemical solution, drinking water, sea water, oil, tap water, hot water, industrial water, corrosive liquids. Ultrasonic flowmeter for air is also available.

They can be used to determine the flow rate in various environments, for example in a paint shop - The flow rate of thick paint is measured by a detector mounted on the pipe already constructed. Or the flow rate measurement in a water purifying system for semi-conductors. They are ideal for determining the flow rate of liquids flowing within large diameter pipes. They are much more economical than electromagnetic flowmeters when used for fluid within a pipe where the diameter is 200 mm or larger.

They can be used to measure the flow rate in an air-conditioning field, or drain flows in two separate pipes and calculating the total value as well as the difference.

They can be used to optimize facilities by diagnosing the flow velocity distribution within piping. Or corrosive fluids in glass, metal and plastic pipes. They can determine the thermal energy received and sent with liquid (water) in cooling and heating. They can also be used in field situations - the portable models need no power supply

Features & Benefits

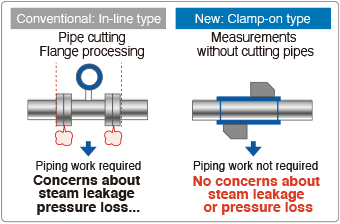

No plumbing required

Installable with no pipe cutting or flange processing. Installable without stopping production lines and no steam leakage concerns since plumbing is not required.

Less maintenance cost

No moving parts help to reduce regular maintenance costs such as cleaning.

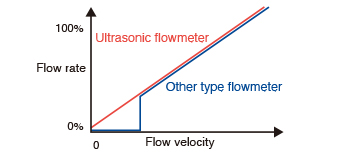

Enables measurements at low flow rates

The ultrasonic flowmeter can meusure at low flow rate, even at flow rates of 0.

Convertible to mass flow rate

The measured volume flow measurement and density (fixed value) input can be converted to mass flow rate and output. Density correction can also be performed by measuring the pressure (4 to 20 mA DC) and temperature (with resistance bulb) of the saturated steam and inputting as external signal (AI).

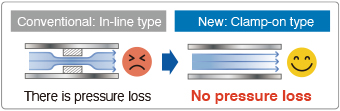

No pressure loss

The ultrasonic sensors do not interfere with the steam flow.

Documentation

Catalog

Solutions

Energy and Utilities

In energy and utility segments, increasing efficiency and cutting down waste are some of the key challenges many ...

Water and Waste Water

Most of the energy consumption in Water and Waste Water Treatment Plant (WTP) is electric power consumption it is ...

Services

Fuji Electric offers a wide range of design and consultation services related to the development of solutions in all of the industry sectors we operate in. Each project requires specific inputs and deep expertise to create the best possible solutions

.jpg)

China

China Europe

Europe France

France Hong Kong

Hong Kong Indonesia

Indonesia Japan

Japan Singapore

Singapore Thailand

Thailand USA

USA